When it comes to operating marketplaces, inventory is the area that needs your utmost attention. Not only does it have to be thoroughly built, but it also has to be managed effectively.

Today’s auto parts market lists tens of thousands of parts across multiple suppliers. Presenting them on your marketplace, along with accurate stock levels, specifications and availability, can prove a significant challenge. This is where real-time inventory synchronization with all its benefits comes into play.

Understanding real-time inventory sync in auto parts marketplaces

Definition of real-time inventory sync

In marketplaces, real-time inventory synchronization is a feature that continuously updates stock levels across all sales channels, supplier databases, and warehouses. But why is it needed?

In short, this real-time inventory sync ensures buyers only see products that are currently available and ready to go. Ultimately, this reduces the risk of canceled orders due to out-of-stock items and a plethora of other issues. Besides, it can help you with:

- Eliminating overselling. Prevents situations where multiple buyers purchase the same item when only limited stock is available.

- Reducing order cancellations. Keeps inventory data accurate, minimizing the frustration caused by last-minute stock unavailability.

- Optimizing replenishment. Helps suppliers and sellers track stock levels in real-time, allowing for better forecasting and restocking.

How auto parts marketplaces operate

As with any other marketplace, auto parts marketplaces are intermediaries between buyers and multiple suppliers (vendors). The latter offers a wide range of components, from OEM (Original Equipment Manufacturer) parts to aftermarket replacements.

Unlike single-vendor stores, these marketplaces must aggregate inventory from various sellers, making inventory synchronization even more complex. Therefore, let’s look into the most common challenges in managing auto parts marketplace inventory.

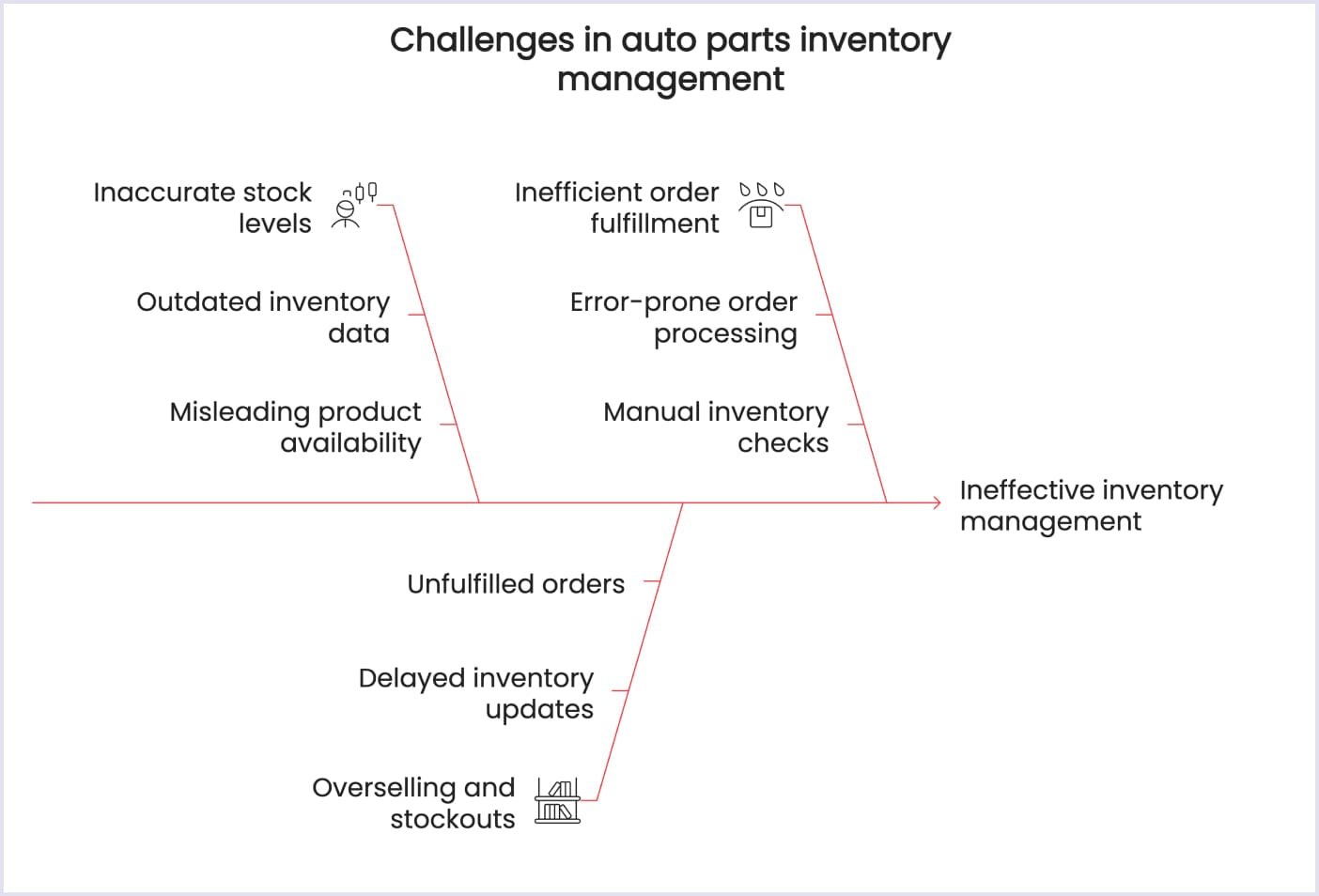

Challenges in managing auto parts inventory without real-time sync

On automotive parts marketplaces, thousands of products from multiple suppliers must be accurately tracked. Managing such extensive inventory accurately creates significant challenges, many of which can only be resolved with real-time inventory synchronization.

Inaccurate stock levels

Without real-time updates, stock levels can quickly become outdated. This can result in products being listed as available when they are actually out of stock, misleading customers and causing failed transactions.

Consequently, inaccuracies cause other issues, like:

- Customers place orders for parts that are no longer available, leading to cancellations and refunds;

- Marketplace credibility suffers as buyers lose trust in product availability;

- Sellers struggle to manage inventory efficiently, leading to confusion in restocking efforts.

Overselling and stockouts

Delayed inventory updates can lead to overselling, where more items are sold than are actually in stock. This often leads to stockouts, where sellers cannot fulfill orders, causing frustration for customers.

As a result, problems arising from overselling and stockouts include:

- Increased customer complaints and negative reviews due to unexpected cancellations;

- Lost revenue opportunities as buyers turn to competitors with more reliable stock tracking;

- Disruptions in supplier relationships as vendors deal with unexpected demand mismatches.

Inefficient order fulfillment

When inventory data is not updated in real time, order processing becomes prone to errors and delays. This impacts the entire fulfillment chain, from warehouse operations to shipping and customer delivery. As a result:

- Orders may be processed incorrectly, leading to shipping the wrong parts or delays in dispatching orders;

- Increased return rates and refund requests due to inaccurate stock information;

- Manual inventory checks slow down operations, leading to backlogs in fulfillment.

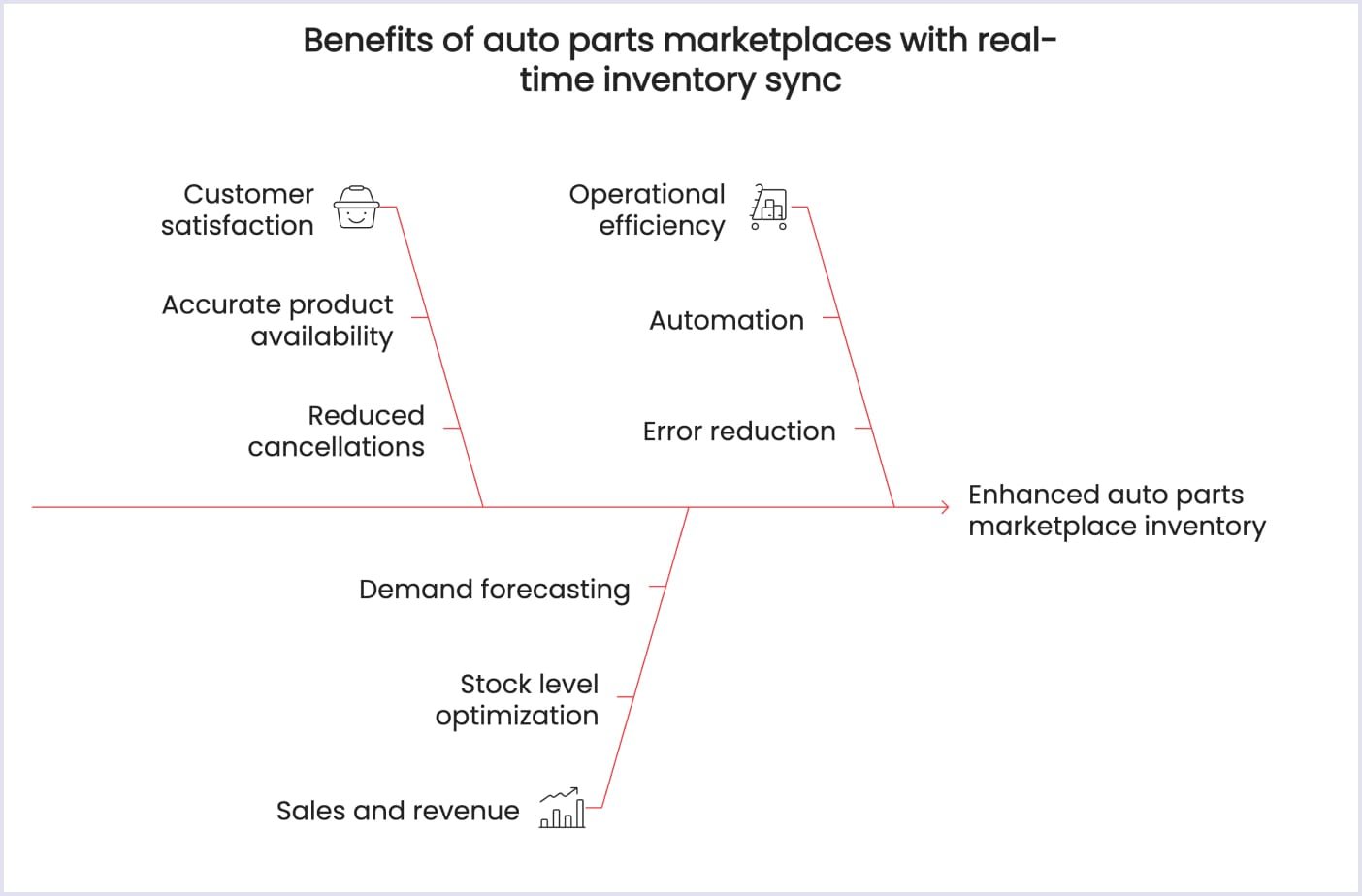

Benefits of implementing real-time inventory sync in auto parts marketplaces

Many of the issues mentioned above can be easily overcome with the introduction of real-time inventory sync on your marketplace. Ultimately, it brings several key benefits.

Enhanced customer satisfaction

Customers expect accurate product availability when shopping for auto parts. If an item is listed as in stock but turns out to be unavailable, it results in cancellations, delays, and frustration.

Real-time inventory sync ensures that stock data is always up to date, preventing misleading product listings and reducing failed transactions.

Consequently, this will increase trust in the marketplace, provide a better shopping experience through instant availability confirmations, and reduce returns and cancellations.

Improved sales and revenue

A well-managed inventory system helps prevent lost sales due to stockouts and overselling. With real-time synchronization, your marketplace can:

- Optimize stock levels based on live demand trends;

- Reduce inventory shortages, ensuring products remain available for purchase;

- Provide accurate alternative suggestions when certain parts are unavailable.

With better demand forecasting and restocking strategies, sellers can maximize sales opportunities and reduce excess inventory costs, leading to higher profitability.

Streamlined operations

Managing thousands of auto parts across multiple suppliers and warehouses requires an efficient system to track inventory without constant manual updates. Real-time inventory sync automates this process, reducing human errors and improving operational efficiency.

With its help, your marketplace can process orders faster, especially with automated stock updates. Besides, it completely eliminates the need for manual inventory tracking, saving time and labor costs.

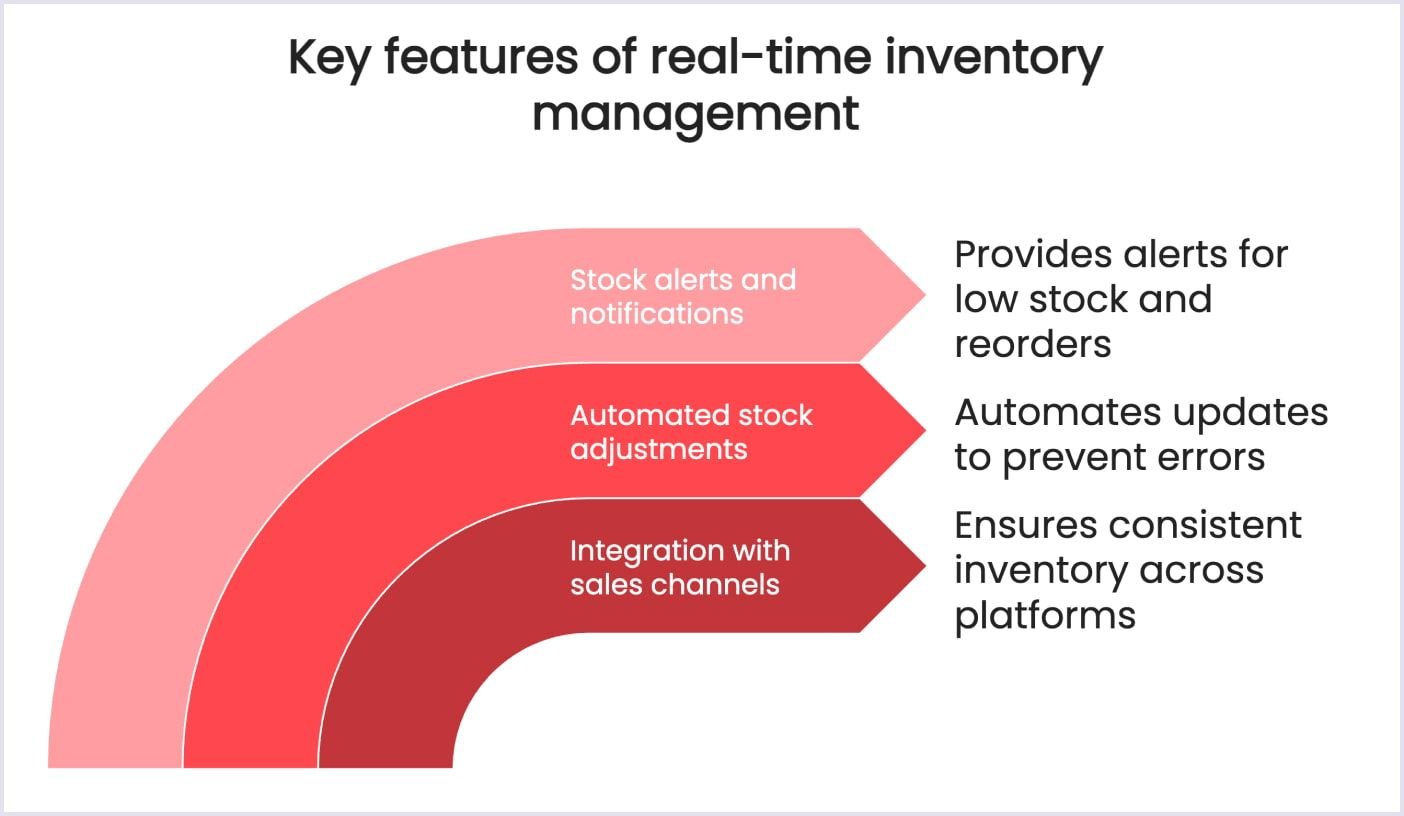

Key features of effective real-time inventory management systems

Now that all the theory is covered, let’s see what features real-time inventory sync should include to negate all the challenges mentioned earlier.

Integration with multiple sales channels

Auto parts marketplaces often operate across multiple platforms, including direct sales websites, third-party ecommerce platforms, and supplier networks. An effective inventory management solution must provide seamless integration across all these channels to:

- Ensure inventory consistency, preventing discrepancies between sales platforms.

- Update stock in real time when purchases, cancellations, or returns occur.

- Synchronize warehouse and supplier inventory to reflect accurate availability.

Automated stock level adjustments

Updating inventory manually can cause dozens of errors and inconsistencies, particularly when dealing with high SKU volumes. Hence, a real-time inventory system must include adjustments of the stock level automation.

Thus, the introduction of this automation provides immediate updates when an item is purchased, returned, or restocked. It dramatically minimizes the risk of overselling and allows accurate reporting that provides suppliers and marketplace operators with real-time stock visibility.

Low stock alerts and reorder notifications

Basically, notifications are great problem-solvers when it comes to important purchases and any missed sales opportunities. A well-designed inventory system includes low stock alerts and reorder notifications, allowing sellers to replenish inventory proactively.

For instance, real-time notifications can be sent to users when inventory drops below a predefined threshold and offer reordering recommendations based on sales trends and demand forecasting.

Last but not least, a clear notification system can greatly prevent customer frustration associated with purchases. As a result, a thoughtful notification system will increase engagement, generate more positive feedback and make purchases much less stressful.

Case studies: success stories of real-time inventory sync implementation

APFusion's real-time price sync

APFusion is a B2B automotive parts marketplace with an impressive number of features. Just like other auto parts marketplaces, APFusion faced challenges in stock accuracy and pricing updates across its supplier network.

To solve this, APFusion integrated real-time price and stock synchronization with its supplier systems. This made it possible to instantly update inventory availability and more accurately adjust pricing to reflect changes in the marketplace. Not to mention a big spike in order fulfillment rates, as buyers had access to reliable, real-time inventory data.

According to their website, users have quick and easy access to over $20,000,000 worth of auto parts. Needless to say, it would be nearly impossible to manage them manually, let alone update their pricing regularly.

Read also: How to Build a Used Car Marketplace

Orderry's marketplace integration

Orderry is an all-in-one business management software, where inventory and stock management are also included.

This feature wouldn’t be as efficient and popular without real-time inventory sync. Hence, by integrating it across multiple online sales channels, Orderry achieved:

- Automated stock updates across all platforms, reducing manual entry errors;

- Better inventory visibility, ensuring parts were accurately tracked across warehouses;

- Expanded sales opportunities, as the system allowed for multi-platform selling without the risk of overselling.

With this implementation, Orderry not only improved the inventory tracking system but also managed to bring more control over stock levels. Ultimately, this integration reduced discrepancies and optimized stock levels, minimizing the need for manual adjustments.

Steps to implement real-time inventory sync in your auto parts marketplace

Assessing your current inventory management system

In case your marketplace is already operational and real-time inventory sync is a planned future feature, make sure to evaluate what you have now.

Identify gaps in your current processes and what needs to be improved. Review how auto parts inventory software data is collected, stored, and updated, identifying pain points, such as manual stock tracking or mismatched availability across multiple sales channels.

Besides, don’t forget to look into your suppliers’ workflows and how frequently they update inventory data. This evaluation will help determine which areas require improvement and how real-time sync can enhance inventory accuracy and efficiency.

Choosing the right software solution

To implement real-time inventory sync effectively, selecting the right software solution is crucial. While some of the off-the-shelf inventory management tools are quite decent, a custom-built solution offers better scalability, flexibility, and seamless integration with your marketplace’s unique requirements. Depending on your marketplace’s specifics, a custom solution should:

- Automatically update inventory levels across all suppliers, warehouses, and sales channels;

- Integrate with existing ERP and order management systems for a unified workflow;

- Provide real-time alerts for low stock and stock discrepancies to prevent shortages;

- Support API connections for suppliers to sync their stock data directly with your marketplace.

Training staff and continuous monitoring

A successful real-time inventory sync implementation doesn’t end with software integration. It needs training and a manual system monitoring by the team. This will help you maintain efficiency and consistency in operations.

- Training staff. Ensure that your team understands how the new system works, including real-time stock updates, order processing workflows, and troubleshooting procedures.

- Supplier onboarding. Work with suppliers to ensure their inventory data is updated in real time and aligns with marketplace requirements.

- Continuous monitoring and optimization. Regularly review sync performance, identify issues like stock mismatches, and refine processes to improve accuracy.

Bottom line

Clearly, not only auto parts-focused, but all marketplaces can place themselves in a winning and safer position with the introduction of real-time inventory synchronization. Compared to traditional approaches, automated inventory updates in real time provide too many benefits to be neglected in the modern market.

Thus, seriously consider implementing it. In case it proves a challenge, feel free to contact us, as Codica is a leading software development company that specializes in marketplace development services.

We’ve built dozens of marketplaces for different niches with varying functionalities and strategies. With each, we introduced a lot of features, be it AI chatbots, multiple payment systems, or smart search systems. Our portfolio lists all these examples, serving as a great demonstration of Codica’s skills and advancements in software development.